Our Location

address

Cut downtime, reduce costs, and gain real-time visibility—no labels,

no RFID, no hassle.

No labels, no scans — just seamless vision

Works in heat, dust, and steam with ease

From coils to chips — no size limits

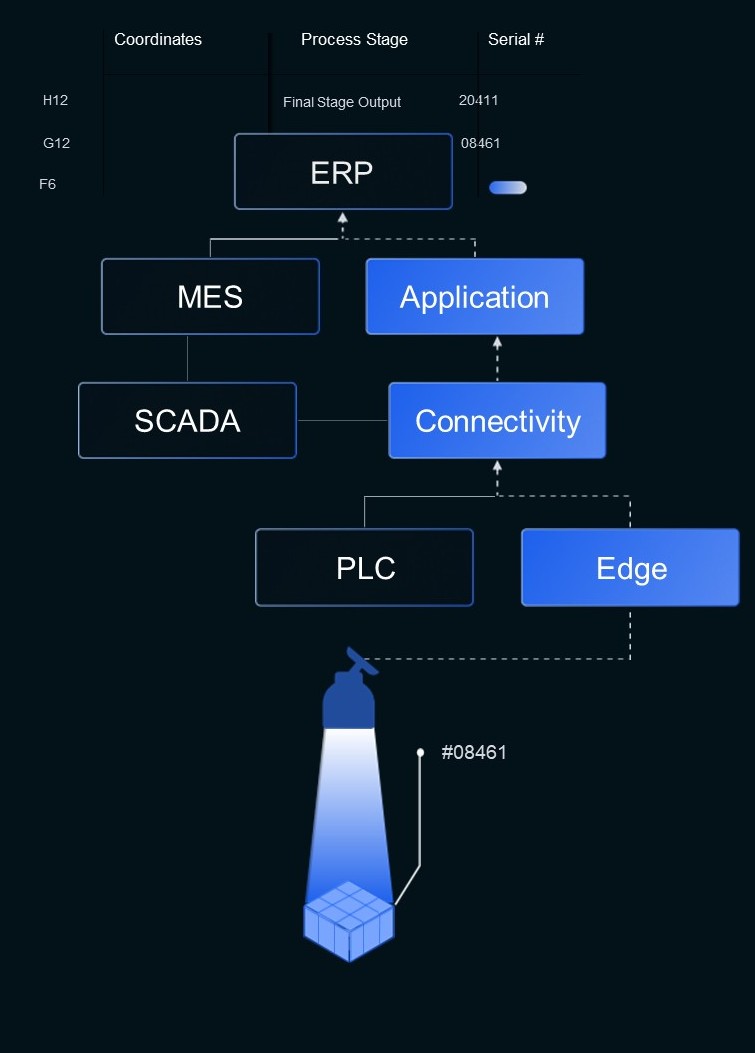

Links with your MES or ERP in minutes

Alat's platform uses advanced computer vision and sensor fusion to track items across your entire production ecosystem. Whether it's a scorching foundry or a high-speed conveyor line, our marking-free approach captures every movement and feeds data directly into your existing systems.

Cameras or LiDAR automatically detect and identify objects, no barcodes or tags required.

Continuous location, movement, and status updates to improve scheduling and inventory control.

Built to endure intense heat, dust, and corrosion—ideal for steel mills, foundries, and beyond.

Connects easily to ERP, MES, or other industrial software with minimal disruption.

Every industry has unique challenges, and Alat is designed to tackle them head-on. Explore our solution by industry or by specific use cases to see how marking-free AI vision transforms workflows, cuts downtime, and increases safety.

Traditional labels fail in the face of extreme heat and dust. Alat's tracking platform thrives in high temperatures, helping you cut re-heating costs, minimize ladle misplacements, and keep production lines running smoothly.

Learn MoreWhether it's forging, smelting, or other intense processes, our solution delivers real-time visibility without manual checks, enabling safer, more efficient operations.

Learn MoreDelicate components deserve precision tracking. Alat's non-contact approach ensures error-free traceability from assembly to final packaging—no risk of damaged labels.

Learn MoreMaintain stringent hygiene and quality control with contact-free item tracking. Our system updates inventory, location, and status automatically, helping you stay compliant and efficient.

Learn MoreReduce scanning overhead, prevent mix-ups on the line, and speed up assembly. Alat seamlessly fits into multi-stage automotive manufacturing for end-to-end visibility.

Learn MoreTired of losing time searching for slabs or coils? Our overhead AI vision locates materials instantly, optimizing yard layouts and forklift movements for reduced operational costs and improved safety.

Learn MoreAchieve real-time monitoring of ladle locations and statuses to avoid temperature drops, reduce energy consumption, and improve safety in foundries and metal production facilities.

Learn MoreMonitor production flow without manual intervention or physical tags, detecting anomalies before they escalate into costly downtime. Ensures smooth and continuous material handling.

Learn MoreCapture continuous data that feeds into your ERP or MES, enabling intelligent scheduling, reduced bottlenecks, and improved operational transparency across your manufacturing process.

Learn More